SUMMARY

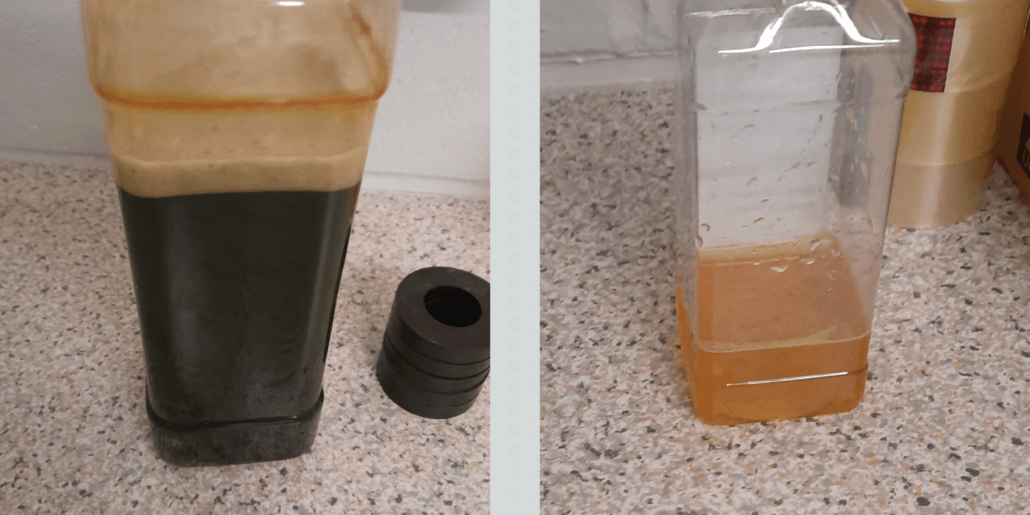

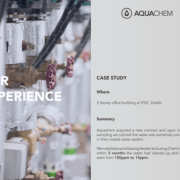

Aquachem acquired a new contract and upon initial water sampling we noticed the water was extremely contaminated in their closed water system.

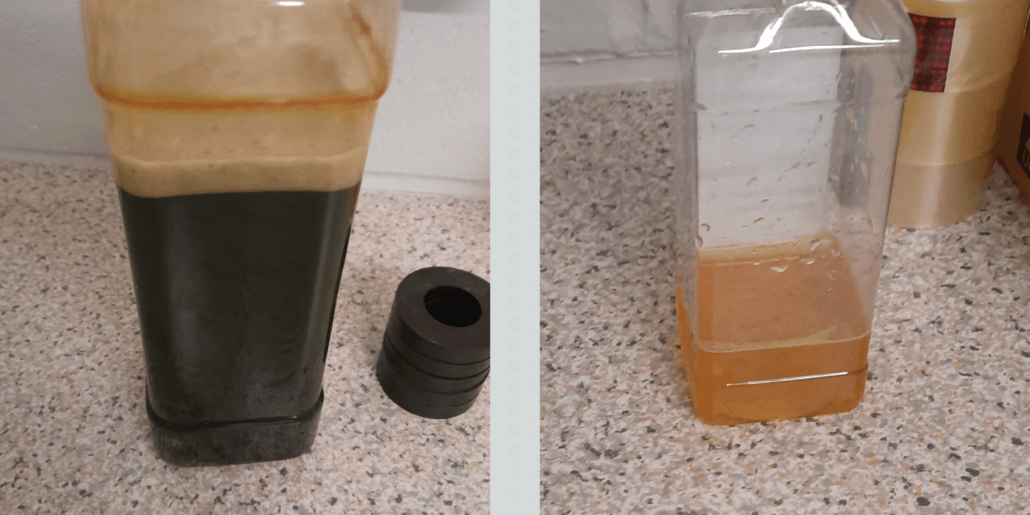

We installed a solid dosing feeder and using Chemhib 3011GS within 3 months the water had cleared up the high iron level in the systems and went from 150 ppm to 15ppm. The sample colour improved dramatically from red/ brown to clear.

WHERE

5 Storey office building at IFSC, Dublin

OVERVIEW

In late 2019 Aquachem acquired a new water treatment contract, when doing the first round of water sampling in their closed water system, visually we could see there was a huge amount of contamination in the water due to it not being treated or managed correctly by the previous water treatment company.

From further analysis the samples showed there was a large amount of iron present, along with other debris.

Due to the serious condition of the water, a plan was put in place and actioned immediately as it was unknown how long the water had been in this state. Contaminated water can cause serious issues in a closed water system, from heat not passing through the system, blockages and corrosion.

It was decided the best course of action was to change from liquid chemical to solid chemicals, and so we installed a solid dosing feeder and implemented a filter system.

We used the solid chemical ChemHib 3011GS inhibitor and noticed the difference almost immediately and within 3 months the water iron levels had reduced from 150 ppm to 15ppm.

Along with the personnel on site, we make sure there are regular filter checks and routine maintenance visits to ensure the water remains at a constant level.

WHAT WAS DONE?

- After reviewing the sample results it was decidedthe best way to treat the contaminated water was to switch from liquid chemicals to solid chemicals

- A plan along with atimeline was put in place to make sure none of the employeesin the building would be disrupted or inconvenienced

- A new filter system was implemented firstin order to remove as much of the contaminates as possible

- We cleared out old liquid chemical drums from the plantroom and had it organized neatly for the new equipment and chemicals to be installed

- The solid feeder was installed

- ChemHib 3011GS was the chemical used for this systems treatment

- The chemical was dosage was calculated and set up accordingly

- A filter, chemical and inhibitor checklist and log was set up

- Personnel on site to check filters and chemicals weekly

- Aquachem to carry out monthly checks and maintenance

- Training was arranged with site personnel to ensure the safe use of new equipment and filters

CONSIDERATIONS

- There office was at full occupancy, so we had to make sure there was minimum disruption

- On site maintenance employees were new to solid chemicals so we had to do training with them on the new chemicals and equipment

RESULTS

The inhibitor levels increased from 50 ppm to 150ppm within 3 weeks of the Greenlife filter being installed, and the iron and other debris was filtered down. The iron reserve dropped from 150 ppm to 15 ppm and the magnets in the greenlife filter were able to take out the iron from the system.

Luckily there was no major damage done to the closed system and the heating systems returned to its full efficiency. Our client was extremely happy with the result and continues to use solid chemicals.

CONCLUSION

Aquachem would always recommend the use of solid chemicals over traditional liquid where possible due to their efficiency and effectiveness along with their other benefits. Changing from liquid to solid can seem daunting however the transition is very simple and will benefit the client in the long run.

The water in this closed system was extremely contaminated and at 150pmm was a major cause for concern, the previous water treatment company was not managing the water system appropriately which could have caused serious damage to their equipment, leading to downtime and major expense to the client.

In this case, we managed solve the problem for our client promptly and efficiently and are pleased with the outcome and continue to look after all their water treatment requirements.