Is your steam boiler running as efficiently as it can?

To ensure your steam boiler is working to its optimum level it is essential that the quality of its feedwater is as pure as it can be.

The feedwater is used to produce the steam, therefore the quality of water going into the boiler will have a profound effect on the safe operation of the equipment. It is vital this is treated correctly.

Boiler blowdown, which is the removal of water from a boiler, is another essential part of a steam boilers operation. It controls the boiler water parameters, within prescribed limits, to minimize scale, corrosion, carryover, and other specific problems.

Essentially, the lower the blowdown rate, the more energy efficient your boiler is and in order to reduce the blowdown rate, the water must be high quality with the least number of impurities.

The delivery of feedwater, collection of condensate and blowdown of a boiler is essential to the most effective operation of a steam system.

Feedwater Treatment & Dosing

Water which is fed to a boiler contains dissolved minerals and gasses which can cause serious damage and without the right water treatment, the plant will suffer from scale and corrosion.

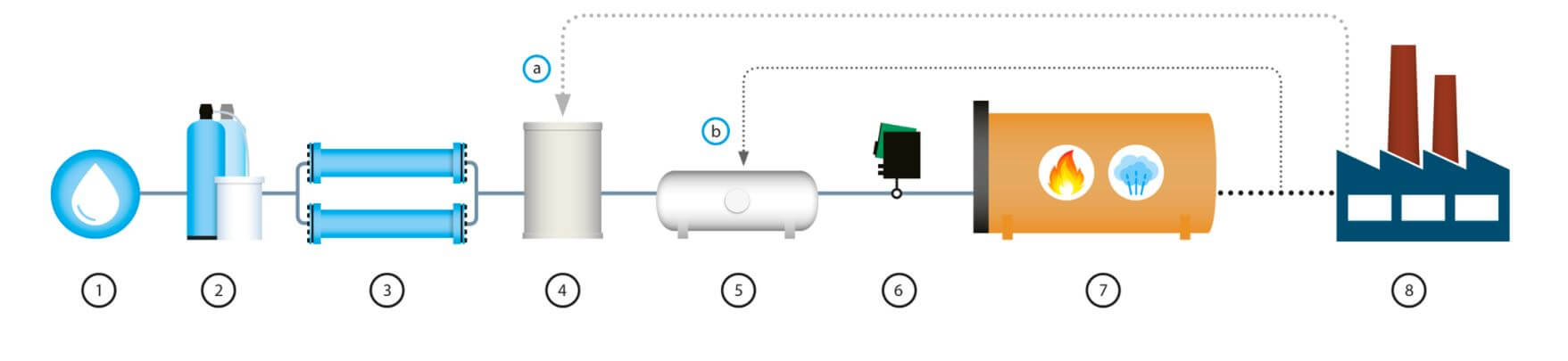

Therefore, the quality of feedwater must be top class which means there are a few processes it must go through before entering the boiler.

The most common form of pre- water treatment is water softening to ensure water contains only non-hardness forming salts. If hardness is present in the feedwater and not controlled chemically, then scaling of the heat transfer surfaces will occur, reducing heat transfer and efficiency.

Feedwater hardness usually ranges from 0.01 to 2.0 ppm, but even water of this purity does not provide deposit-free operation. By softening the water, scaling is prevented but the content of bicarbonate of the raw water passes through the softening plant which is why another course of treatment is required.

1. Raw Water 2.Softening 3. Demineralisation 4.Water Tank 5.Degassing 6.Dosing Pump 7.Steam Boiler 8.Production

How chemical dosing works

The most efficient way to treat the water in the next phase is solid dosing. This is where dosing units dose chemicals straight into the return/feed water tank or the boiler feed water line.

The dosing units are designed to release a specific amount of chemical into the water system at certain times. The dosage quantity and frequency is calculated by a number factor including flow rate, size of equipment, usage etc. Once this is calculated and set up it can be remotely monitored to ensure there are no discrepancies appearing in your water system.

Boiler feedwater chemicals need to be applied and maintained at specified concentrations for their desired effects to be achieved. And when these uniform concentrations are maintained in the boiler water, savings also result in a number of areas, including makeup water demand, cost of processing water, cost of blowdown water waste treatment, fuel consumption, and chemical treatment requirements.

Impurities within boiler feedwater can cause problems with the efficiency of steam boilers and steam systems. It is usually necessary to chemically treat feedwater to remove or modify impurities.

In order to ensure the safe, efficient and economical running of the steam boiler it is imperative that the boiler feedwater is sampled for analysis at regular intervals.

Boiler Blowdown

Blowdown is used to remove suspended solids present in the system. These solids are caused by feedwater contamination or by internal chemical treatment precipitates.

By minimizing boiler blowdown, you will save water and energy.

In high quality boiler water, levels of suspended and dissolved solids are down to a minimum. This will minimize blowdown volume and hereby reduce energy loss, as the temperature of the blowdown liquid is the same as the steam generated in the boiler. Lower blowdown rate will also reduce makeup water and chemical use, saving you money and water.

For example, the blowdown can range from less than 1% when an extremely high-quality feedwater is available and then can be greater than 20% in a critical system with poor-quality feedwater.

The blowdown rate required for a particular boiler depends on the boiler design, the operating conditions, and the feedwater contaminant levels. Sometimes, certain boilers may require lower than normal blowdown levels due to unusual boiler design or operating criteria or an exceptionally pure feedwater requirement.

Energy Conservation

There are several factors which can contribute to the reduction of energy consumption on the water side of steam boilers;

Blowdown Reduction

Blowdown rate is often the most poorly controlled variable of an internal treatment program, and as outlines above, reduction in boiler water blowdown can result in significant fuel and water savings.

Heat Recovery

Heat recovery is used frequently to reduce energy losses that result from boiler water blowdown

Scale Reduction via pre water treatment

Heat transfer is inhibited by scale formation on internal surfaces. Scale reduction through proper pre treatment and internal chemical treatment results in cleaner internal surfaces for more efficient heat transfer and resultant energy savings.

It is not necessary to know chemistry to appreciate the fundamentals of water treatment. Good water treatment practice is dependent on a suitable treatment regime for the whole system; from the cold feed to the returning condensate.

The purpose of boiler water treatment is to protect the boiler and steam system against corrosion and scale formation and help maintain steam purity and quality. Poor quality feedwater will lead to poor quality steam, increase energy costs, reduce efficiency, reduce plant life and the boiler will be unreliable and unsafe.

Without effective water treatment, you will almost certainly be spending more than you need to on energy, water and effluent charges.

AquaChem are specialists in steam boiler water treatment and have a comprehensive range of boiler water treatment chemicals, dosing systems and water softeners.

For more detail on the principles of boiler water treatment call Aquachem on 018 252 775 or visit our website aquachem.ie