Steam Boiler Maintenance & Safety

Steam boilers are one of the most important pieces of equipment in industry and are used in industrial buildings including hospitals, universities, laundry services, food processing services, breweries and factories. All industries rely on some type of steam boiler system to provide heat and/or hot water for their operations.

Steam boilers can cost over a hundred thousand euro to purchase and so ongoing boiler maintenance is key to safe operations. Make sure you have a look at the new boiler cost and see which one is feasible for your budget. Due to their importance, preventative maintenance (PM) is crucial for all industrial steam boilers in order to maximize uptime and minimize repair costs.

How the boiler works?

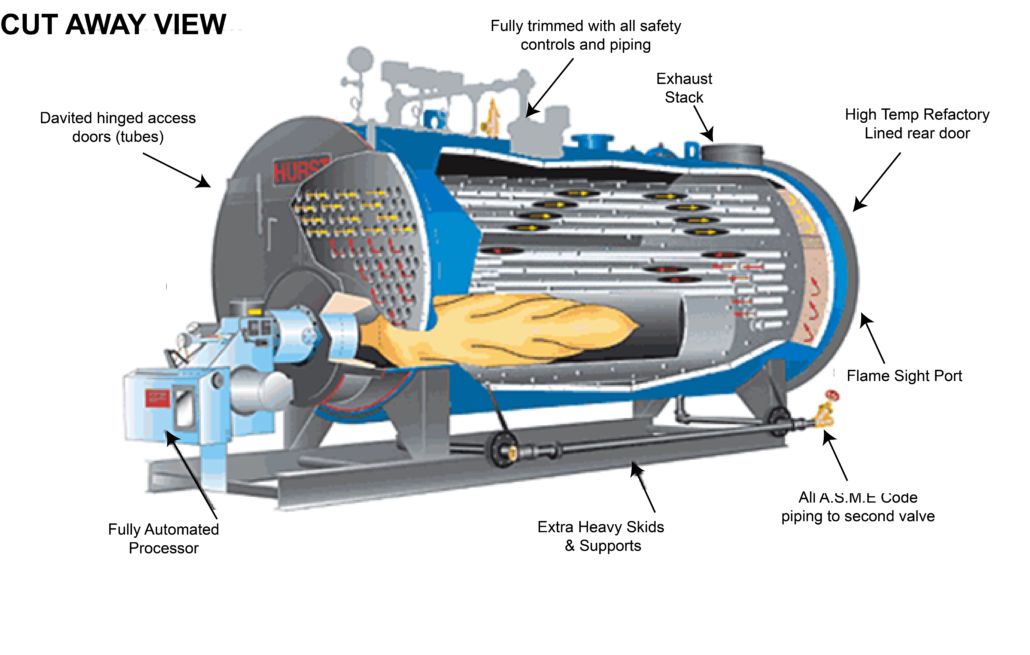

Industrial steam boilers are similar to the household heating boilers except the industrial boilers are significantly larger. They are very complex pieces of equipment and there are two main designs of steam boilers: water tube and flame tube/smoke tube (otherwise known as a shell boiler).

In a water tube boiler, water is contained in tubes that are surrounded by hot gas whereas in a shell boiler, hot gas flows through tubes that are surrounded by water. In both cases, the hot gas heats the water.

The boiler itself is a large horizontal cylinder which has insulation around it, they are usually approx. 75% water, allowing a 25% gap for the steam.

Within the boiler, the flame tubes sit in the water. Hot gas enters the flame tubes (first pass) and continues through an internal reversing chamber that reverses the flue gases, leading them into the smoke tube (second pass). An external reversing chamber reverses the flue gas a second time, leading it into another smoke tube (third pass). Once the gas has moved through the third pass, it exits through a chimney. The heated water then turns into steam.

The steam is then transported around the system via pipes and hot water will be pumped to taps.

Maintaining your steam boiler

Regardless of the boiler type, a proper maintenance programme should be implemented to ensure your plant is operating as efficiently as possible.

The build-up of scale and other deposits in steam boilers and system pipework reduces the efficiency of equipment. This can cause the boiler to be dangerous to operate and could lead to loss of revenue through down time. The more scale you have on the water side of the furnace, the more heat loss you have which results in more fuel being required to produce the required amount of steam.

The most obvious advantage of regular maintenance is to prevent boiler failure, however it also:

- Increases safety and reliability

- Reduces replacement costs

- Increases energy efficiency

- Better inventory management

- Increases energy efficiency

- Reduces downtime during steam boiler annual inspection

While these advantages are significant, it is also important to take into account the less obvious costs associated with component or system failure, like potential lawsuits and general loss of goodwill – if a serious incident was to occur. That’s why the following three items identify the crucial reasons for maintaining your steam boiler.

1. Maintain Water Quality

The efficiency of your industrial steam boiler is directly connected to water quality. The boiler converts water into steam, any impurities in the water will reduce the quality of the steam. This will result in wasted energy and higher operating costs.

Boiler maintenance includes having water chemically tested, these results will indicate if the water quality is good enough to stop corrosion, the build-up of scale and other problems that will shorten the lifespan of the boiler.

Salt can also quickly build up in a steam boiler, which could lead to corrosion of the boiler, this is due to when water evaporates, the salts that are naturally in the water cannot evaporate.

2. Ensure Proper Boiler Blow Down

Blow down is the process of draining water from the boiler periodically. This is essential because solids dissolve in the make-up water as the boiler removes pure water in the form of steam.

The bottom of the boiler contains the greatest amount of sludge, the drain valve enters the boiler slightly below water level, where the concentration of dissolved solids is highest. Proper blow down is a central element of boiler maintenance to prevent dangerous sludge build-up.

3. Facilitate Appropriate Insulation

Insulation is vital to the safe and efficient operation of a steam boiler. There is a variance in the amount of insulation required, as well as the material the insulation is made from depending on the size of the pipe and its temperature in operation.

Insulation maintenance includes inspecting the piping, boiler surfaces and fittings.

Water Treatment

Water treatment should be implemented as part of the boiler system design to prolong the life of the boiler. A water treatment programme will involve:

Water softeners

The most common form of water -treatment is water softening. The water softeners remove the hardness from the water.

Chemical dosing

Impurities in the boiler feed water can cause problems with the efficiency of steam boilers and steam systems. It is usually necessary to chemically treat the feed water to remove or modify impurities.

Water sampling

In order to ensure the safe, efficient and economical running of a boiler plant, it is imperative that the boiler water is sampled for analysis at regular intervals.

AquaChem provides an extensive range of advanced steam boiler treatment programmes which have been developed for use with all types of systems ranging from low, medium and high-pressure systems.

These products prevent scale, oxygen and condensate line corrosion, sludge formation and foaming. They also help customers to operate their plants at maximum efficiency while reducing energy costs.

Get in touch with us for more information.