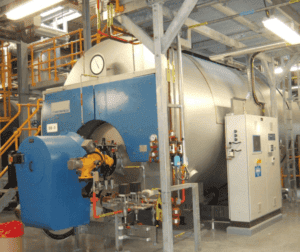

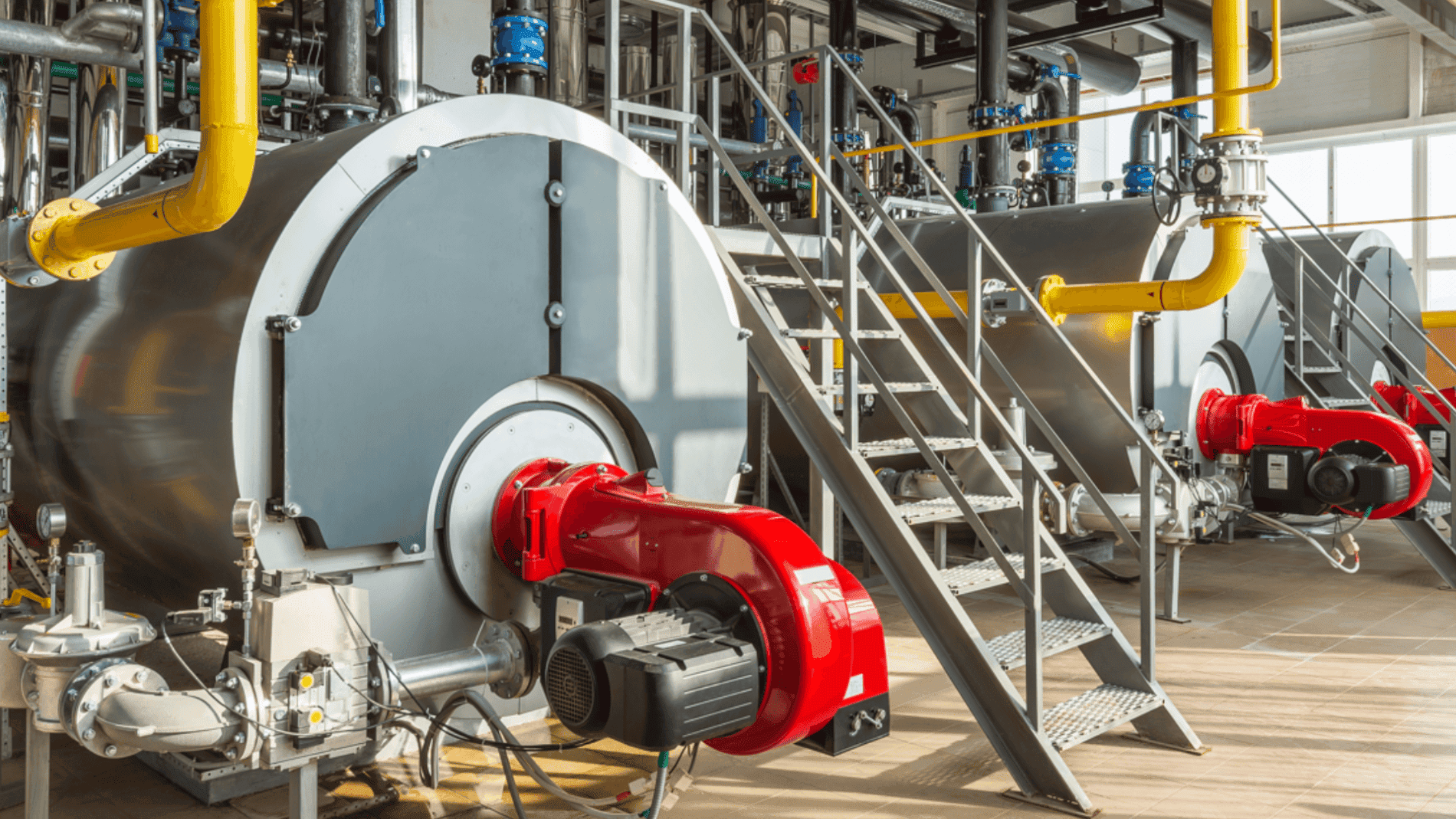

A water treatment plan should be an integrated aspect of the boiler system design to prolong the life of the boiler, this usually involves:

- Water softeners; The water softeners effectively remove hardness from the water.

- Chemical dosing; Impurities in the boiler feed water can cause problems with the efficiency of steam boilers and steam systems. Chemical dosing is typically necessary to treat the feed water and to remove or modify impurities.

- Water sampling; In order to ensure the safe, efficient and economical running of a boiler plant, it is imperative that the boiler water is sampled for analysis at regular intervals.

The most obvious advantage of regular maintenance on your steam boiler is to prevent boiler failure, however it also: