The use of solid chemicals in water treatment is becoming more popular within the industry due to their advantages over liquid chemicals, but how does it actually work?

Chemical dosing systems are found in all parts of water treatment and are used for various reasons such as: reducing bacteria; reducing scale and corrosion; and to ensure systems run efficiently.

Traditionally liquid chemicals were always used in water treatment however with the world focusing on climate change and what businesses can be doing to lower their carbon footprint, along with increase energy and storage costs organisations have been making the switch to solids.

_____________________________________________________________________________________________________________

The solid chemical dissolvers and dispensers are ideal for the automatic treatment of boilers and cooling towers.

The solid chemical dissolvers and dispensers are ideal for the automatic treatment of boilers and cooling towers.

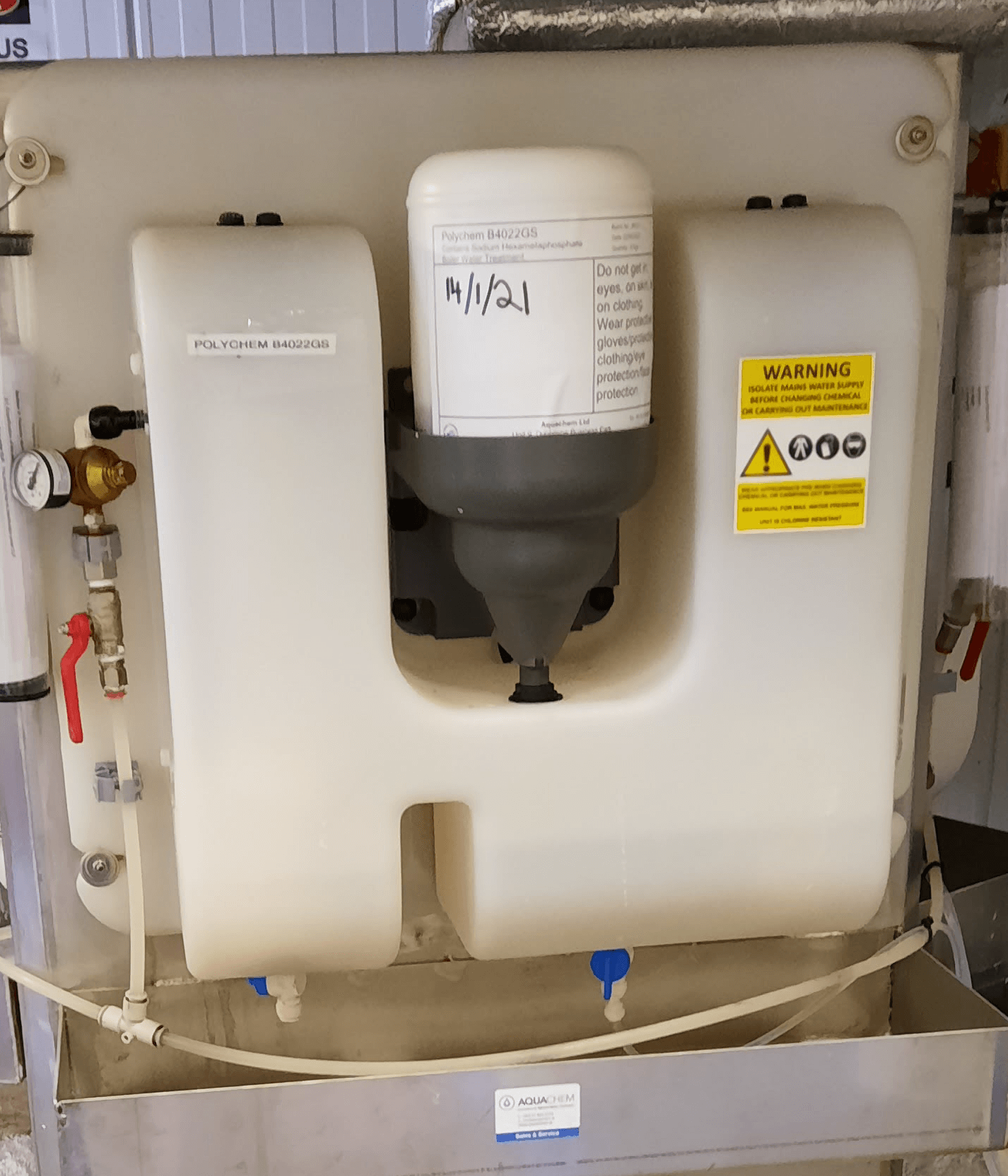

The chemicals are a solid concentrate in a container which is inserted into compact, wall mounted dosing units, taking up a lot less space than liquid chemical drums.

Water is then sprayed at a constant pressure hitting the solid chemical, which dissolves the chemical and creates a solution / emulsion. This fills the reservoir located below, when the reservoir is full a sensor will shut off the water supply.

This solution is then pumped into the systems at a controlled amount.

When the reservoir is low, the sensor will trigger the systems and it will activate the flow of water and repeat the process.

Most existing pumps, controllers and other equipment used with liquid water treatment products may be adapted for use where applicable.

_____________________________________________________________________________________________________________

Solid chemicals have a number of environmental benefits (view here) but they have a number of other advantages over liquid chemicals, including:

- Reduces risk of injuries associated with drum handling, chemical spills, and splashes

- Smaller footprint simplifies transportation, storage, and installations in tight spaces

- Ideal for hard to access systems that require delivery up steps or through office spaces

- Less packaging, landfill waste, and transportation related greenhouse gas emissions

Benefits include:

- Powered by normal line water pressure

- Utilises low cost, reliable and proven float technology

- Small footprint

- on-demand pumping when indicated by the system controller

- Adjustable pressure regulator and removable filter

- Low maintenance

- Models available with back-up float system and reservoir for overflow protection

- Automatically adjusts for conductivity changes in the incoming water

- Improved scale and corrosion protection

- Reduced Legionella Risks

- Plant Longevity

- Saving water and Energy

- Peace of mind

- Continual operation of Cooling System without compromise

_____________________________________________________________________________________________________________

Solid dosing is a water treatment solution that eliminates the handling, safety, and environmental concerns associated with using liquid chemicals in pails or drums.

Solid chemicals are applicable to both small and large systems and are ideal for water systems where storage space is limited or some locations are hard to reach.

Contact us today to discuss our range of solid chemicals and water treatment solutions.