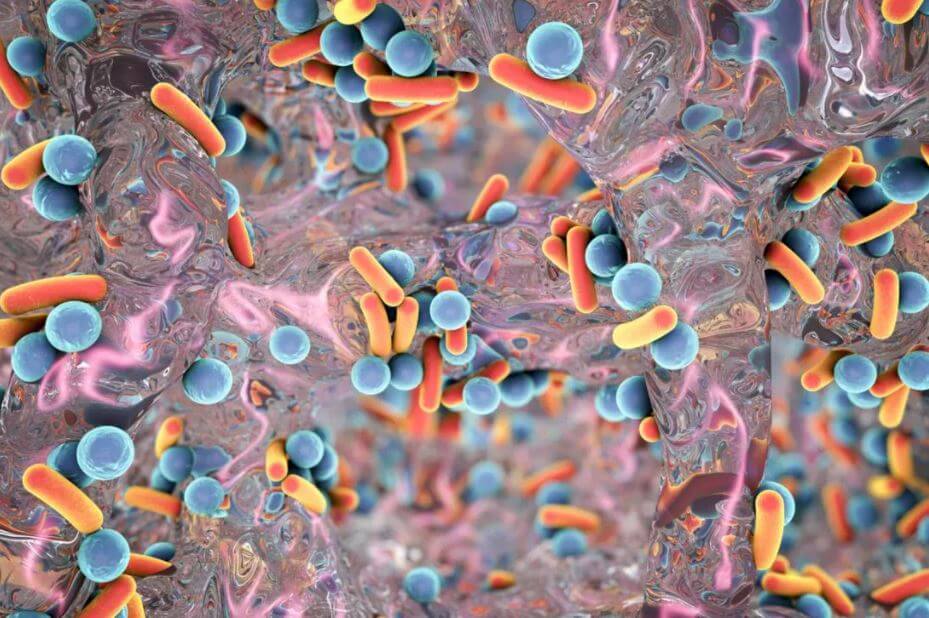

Biofilms are a large group of previously free-floating microorganisms that have colonised, stuck together and adhered to a surface.

They have a complex amicrobial architecture that encases microbial cells in a matrix, simply put they are a bacterial slime layer which protects a host of bacteria and microorganisms which can be dangerous to public safety and health.

They can occur within pipes, tanks, industrial cooling towers, heat exchangers, hospital plumbing system, filter media, etc.

Biofilms are very difficult to remove because of their architecture, along with its ability to adapt to the environmental conditions. The biofilms organise themselves into a co-ordinated functional community, sharing nutrients and protecting themselves from harmful factors within their environment. Its’ cells are specialized to perform different roles, enhancing the survival of the entire group under adverse conditions.

Biofilms are very difficult to remove because of their architecture, along with its ability to adapt to the environmental conditions. The biofilms organise themselves into a co-ordinated functional community, sharing nutrients and protecting themselves from harmful factors within their environment. Its’ cells are specialized to perform different roles, enhancing the survival of the entire group under adverse conditions.

.

Prevention

Biofilm removal is the most important part of any drinking water treatment system. If the chemical product used does not have the ability to remove biofilm it is impossible to have a safe pathogen free environment.

Biofilm forms when microorganisms such as bacteria, fungi, yeasts, viruses, algae and protists stick to each other and grow on a surface. In the built environment biofilm formation occurs very easily in moist warm conditions, particularly if the water with which the film has contact is still or stagnant. Showerheads are a good example; pipework is another.

To help prevent the build up of Biofilms, thought must be taken from the start – the design of your water system.

Ensuring that system design is appropriate and will prevent the accumulation of biofilms, sediments and deposits.

Biofilms form quickly if water remains stagnant in the water distribution system, the stagnant water in dead legs provides ideal conditions for biofilms to form. Without flow, the water in a dead leg does not receive disinfectant or biocide treatment. This allows bacteria to attach to system surfaces to start the biofilm formation process.

The general requirements for well-designed pipework are:

1 . Smooth internal surfaces.

Microorganisms adhere less well to smooth surfaces than to rough surfaces, therefore corrosion resistance and avoiding rouging (iron oxide formation) is important (as can be achieved by the electropolishing of stainless steel).

2 . Continuous water movement in tanks and rapid flow in pipework;

velocities in the range of 1–2 meters per second have been found to be satisfactory.

3 . Avoidance of leakage.

Water leaks can cause bridging of water to the external environment through which bacteria may enter the system. Storage tanks should be equipped with filter on their air vents to prevent air-borne microbiological ingress.

4 . The use of coated surfaces on pipes and in tanks, where appropriate (as not to pose a risk of leaching toxic substances) can help to address bio-fouling.

5 . Storage tanks

Water storage tanks are normally constructed from stainless steel. Where they are used, it is important to determine capacity, rate of use, and frequency of flushing and sanitizing the internal surfaces. Regular water turnover helps prevent contamination; slow turnover, on the other hand, presents a greater potential contamination risk.

If they are poorly designed or improperly maintained, pipes and tanks are more likely than any other part of the water system to develop contamination.

Another key way to help prevent biofilm is to stop the ingress of oxygen. Like all living things, most bacteria need oxygen to thrive so to limit this would help in the fight against biofilms.

Control

The problem with drains and pipes is they’re hard to see down and even harder to reach, which makes cleaning them extremely difficult. To remove and control biofilm, you must first break it down, a few other ways to help control biofilm forming in your water systems include:

- Ensuring that chemical additives used to control scaling, corrosion and microorganisms are applied at appropriate and effective concentrations and are chemically compatible (i.e. non-reactive) with one another and with the system

- Consider the properties of materials used in the water system (g. insulating properties, the potential for corrosion, interaction with chemical disinfection processes)

- Use filtration in systems where water quality is poor and water is recirculated. Filtration of water entering a system can remove particulates and organic matter, reducing the rates of biofilm formation and Legionella growth.

- Preventing low flow rates and stagnation of water is an essential and important control measure, and the system should be designed to minimize areas of stagnation and low flow.

Once the system is in-situ, pre-commissioning cleaning, in-line with guidelines is essential, as is ongoing maintenance. In the fight for biofilm removal, it is important that after-care is well planned and fit for purpose.

Frequent monitoring is important to verify microbiological control.

Conclusion

The best method to fight the presence of biofilms is to prevent their formation from occurring in the first place.

Biofilms can be dangerous to human health, but also harmful to a wide range of industries, including farming, horticulture, food and drink. But with their slimy coatings, biofilms are resistant to many treatments, and as we have described, biofilms can easily generate new colonies of bacteria.

By understanding your water system and how it works, you will know better how to fight against biofilm formation.

If you want to find out more about Biofilms and how they are formed please visit – https://www.aquachem.ie/blog-2/what-exactly-are-biofilms/