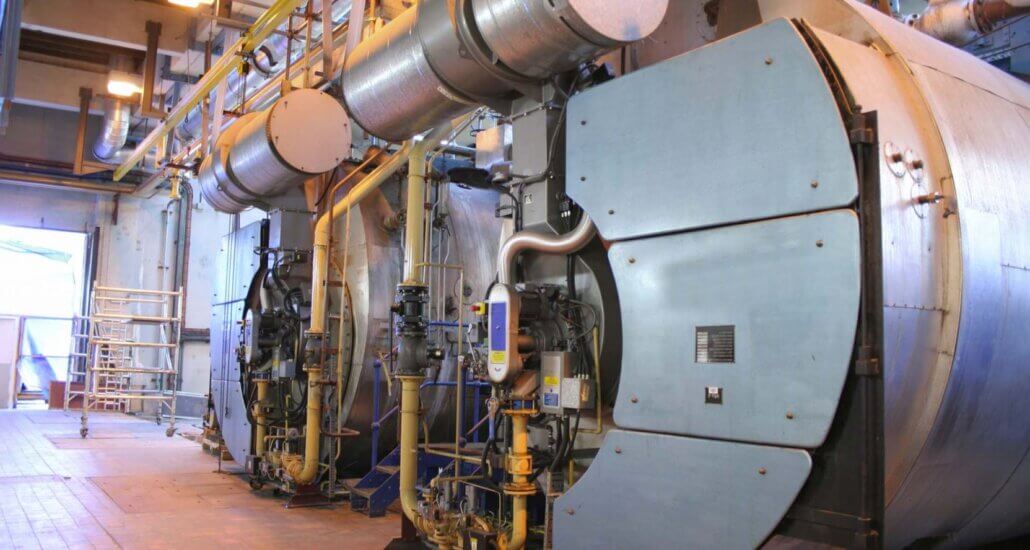

Steam boilers are one of the most hardworking pieces of equipment in most commercial buildings and the must always remain reliable and efficient. Regardless of what industry you are in, the need to operate a boiler efficiently and cost effective in todays’ environment is at the top of every facility / building mangers’ agenda.

A steam boiler consists of pressurised systems that burn fuel or use electricity to heat water and turn it into steam, this steam moves through pipes in the building and enters radiators and/or other elements which heat the building.

Due to their demand, commercial boilers come under a lot of stress which can significantly reduce their lifespan and it is vital that it is taken care of to avoid any breakdown which will occur additional operational cost and possible loss of profits.

To help ensure your boiler is operating at peak efficiency we have listed a few guidelines which can help improve the overall performance of your boiler and allow your building / facility to achieve a more cost-effective maintenance and operational programme.

Preventative maintenance

Preventative maintenance is a must when it comes to your boiler working effectively and safely. This should be carried out by professionals due to the high pressure and temperatures of the equipment with steam boiler leaks leading to serious damage or injuries.

The main objective of a boiler treatment plan is to ensure the water quality remains high and it is free from deposits and there is no build up of corrosion in the system. Preventative maintenance should be carried out AT LEAST once a year with daily inspections being carried out on site daily. Below is a list of tasks which professionals should carry out:

Regular cleanings

Residue such as hard water deposits, soot, scale, and other contaminants can build up, and if this coating residue is as thin as 0.03-0.05 inches thick, it can reduce heat transfer efficiency by up to 10%. The more residue that builds, the less efficient the heat transfer, and the greater the chances of a breakdown, a thorough cleaning should be carried out at least once a year.

Water quality

Water quality affects the continued operation of your boiler greatly, so you should regularly check and test the water inside your boiler for dissolved materials, organic matter, and returned condensate. Plumbing companies or HVAC services can assist in inspecting your boiler and its water quality.

Insulation

Insulation helps steam boilers work efficiently. Condensate piping, fittings, or valves that are uninsulated lose heat, reducing efficiency and increasing costs.

Maintain accurate inspection logs

Consistent log-keeping helps you know which boilers were inspected. It also helps ensure proper maintenance and that even slight performance reductions are tracked. You must record which boiler has been inspected and what was done to it in order to keep an accurate account of its condition.

Daily Inspections

As previously mentioned, your boiler should also be checked daily by site personnel to detect any problems early onl. A daily check list should consist of the following:

- Ensure the area around the boiler is unobstructed and that no materials could obstruct it

- Check for leaks under and around the boiler

- Check temperature and pressure readings are within range

- Listen carefully to check for any noises or vibration

- Look out for error codes appearing on the dashboard panel

- Inspect the combustion air openings for blockages

If there is anything out of the ordinary get in touch with your water treatment specialist immediately.

Get Insulation

Adding insulation is essential to ensure any build up of condensation is drained away from the boiler. Uninsulated piping can reduce the efficiency of the boiler, resulting in higher energy bills.

It is also vital insulation is on any surface with a temperature over 130 degrees Fahrenheit to protect people from injury and other equipment from getting damaged.

Water Quality

Your boiler turns water into steam and for this reason it is important that your water is of good quality and clear of oil or other impurities. Problems with your boiler such as wet steam and short cycling are caused by dirty, contaminated water and they can be the cause of wasted energy and increased costs.

These risks can be reduced by carrying out the daily checks; if you check the gauge and look for signs of a dirty boiler, if water is bouncing vigorously behind the glass, it could mean that the water has oil in it. Additionally, if water drips from the top of the gauge, wet steam is leaking from your boiler.

These conditions will make your boiler work doubly hard as wet steam does not provide enough heat. A full water treatment system may be the solution to this problem. Have your boiler water tested by a professional to ensure that no corrosion or scale build up has formed due to poor water quality.

Reduce excess air

Another consideration when trying to improve efficiency is look at how excess air levels are being controlled. With a properly designed O 2trim system, the boiler will maximize combustion efficiency and minimize heat loss up the stack.

An often-stated rule of thumb is that boiler efficiency can be increased by 1% for each 15 %reduction in excess air.

In order to maintain excess air at optimum levels, ensure that boiler control systems are working properly and periodically have a qualified boiler/burner technician re-tune the boiler’s burner.

Boiler blowdown

There are two types of boiler blowdown: continuous and bottom.

Continuous blowdown removes dissolved solids from the water surface and is continuously operating whereas bottom blowdown removes sediment that has settled to the bottom of the boiler and generally is used several times a day.

The energy contained in the continuous blowdown can be used to preheat feedwater and supply flash steam to a deaerator, reducing overall steam required by the deaerator. Flash tank systems or a blowdown heat recovery system with a flash tank and a heat exchanger are two methods for recuperating energy in the blowdown.

Down time affecting your system

All of these guidelines not only help increase the efficiency of your boiler, they will prolong its lifespan and reduce (hopefully eliminate!) downtime of the equipment.

Whenever the boiler is shut off, the heat will continue to radiate through – this lost heat is called downtime losses, these losses can affect different efficiencies in many ways.

Equipment downtime will also result in additional labour costs and loss of production so it is imperative all is done to minimise the risk.

Conclusion

There are many ways to make sure that your commercial steam boiler works as efficiently as possible. To help ensure that your building remains comfortable and that your boiler remains in peak operating condition, you should the steps mentioned to help keep it running as efficiently as possible.

Contact us today to see if there is anything else you can be doing to help increase your steam boilers efficiency.