Have you made the switch to solids yet?

For a long time, liquid chemicals have been the preferred choice of water treatment for cooling towers, boilers or closed loop systems, however businesses are now realising there are numerous advantages for using solid chemicals instead.

There is the old saying “if it’s not broken don’t fix it”, which is often the case when it comes to water treatment in the industry, especially when there has been no issues with your water while using your current method of water treatment. Switching to solid chemicals means there will be a transition period where training of personnel will be required and ofcourse there will be an upfront cost for the new equipment, chemicals and installation – so why would an organisation make the change?

There are many risks associated with liquid chemicals, health and safety wise & environmentally, by switching to solid chemicals these are eliminated. Environmentally, switching to solid chemicals not only has an impact on water savings but CO2 reduction is a direct result of switching to solid chemistry. Assuming a 2,000 ton average load at 5 cycles of concentration, switching from liquids to solids can reduce CO2 emissions by 56 tons annually.

Changing from liquid chemicals to solid chemicals is a lot easier and quicker than you think, and while there may be an upfront cost when making the switch to solids, in the long run the savings will by far offset this cost, and while there may be a period of adjusting to the new equipment and chemistry, we can confidently say this will not take long to get used to. You will soon see the difference in your energy and water usage, and the positive impact you are making in your business and the environment.

Benefits of making the switch?

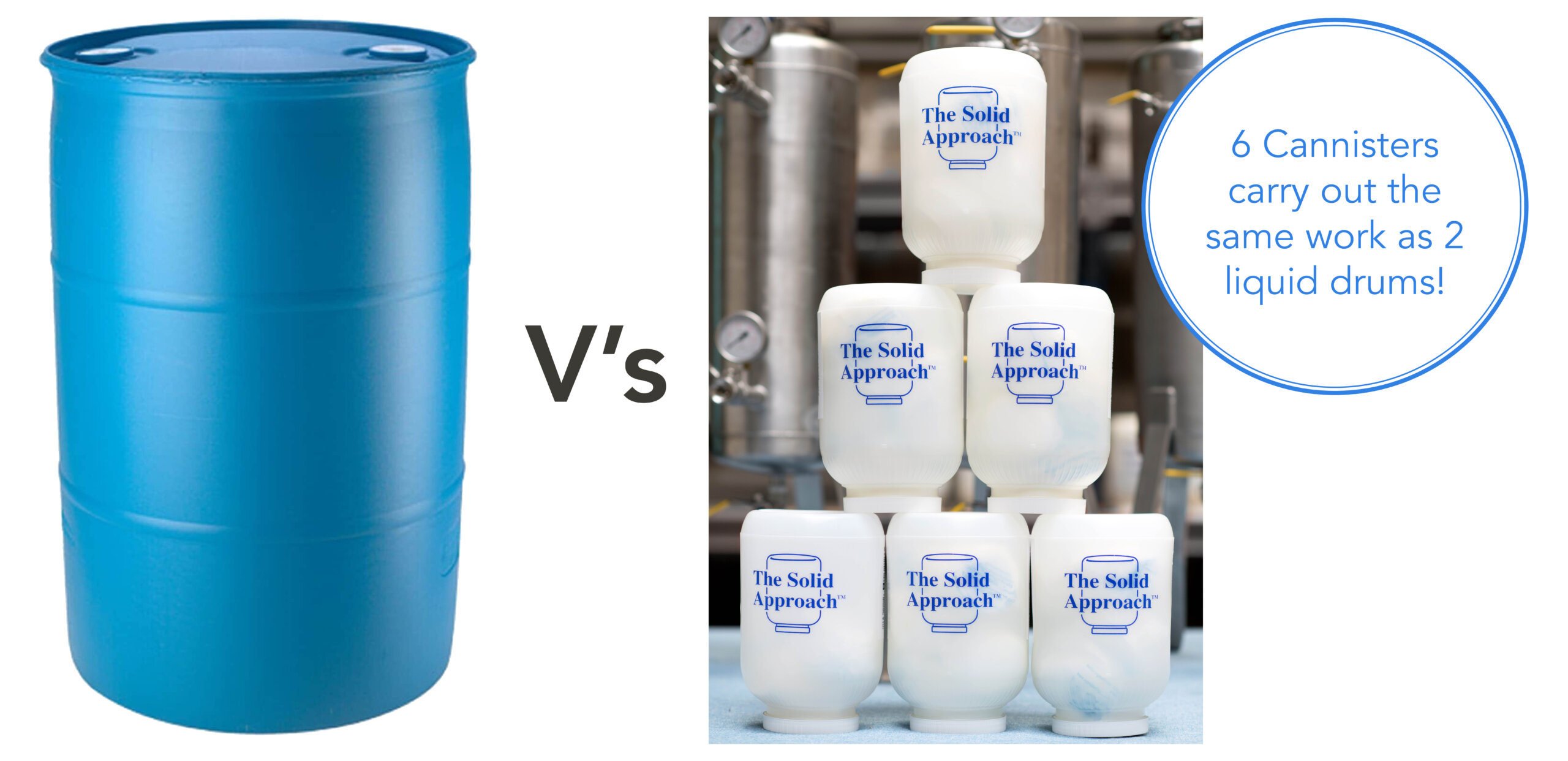

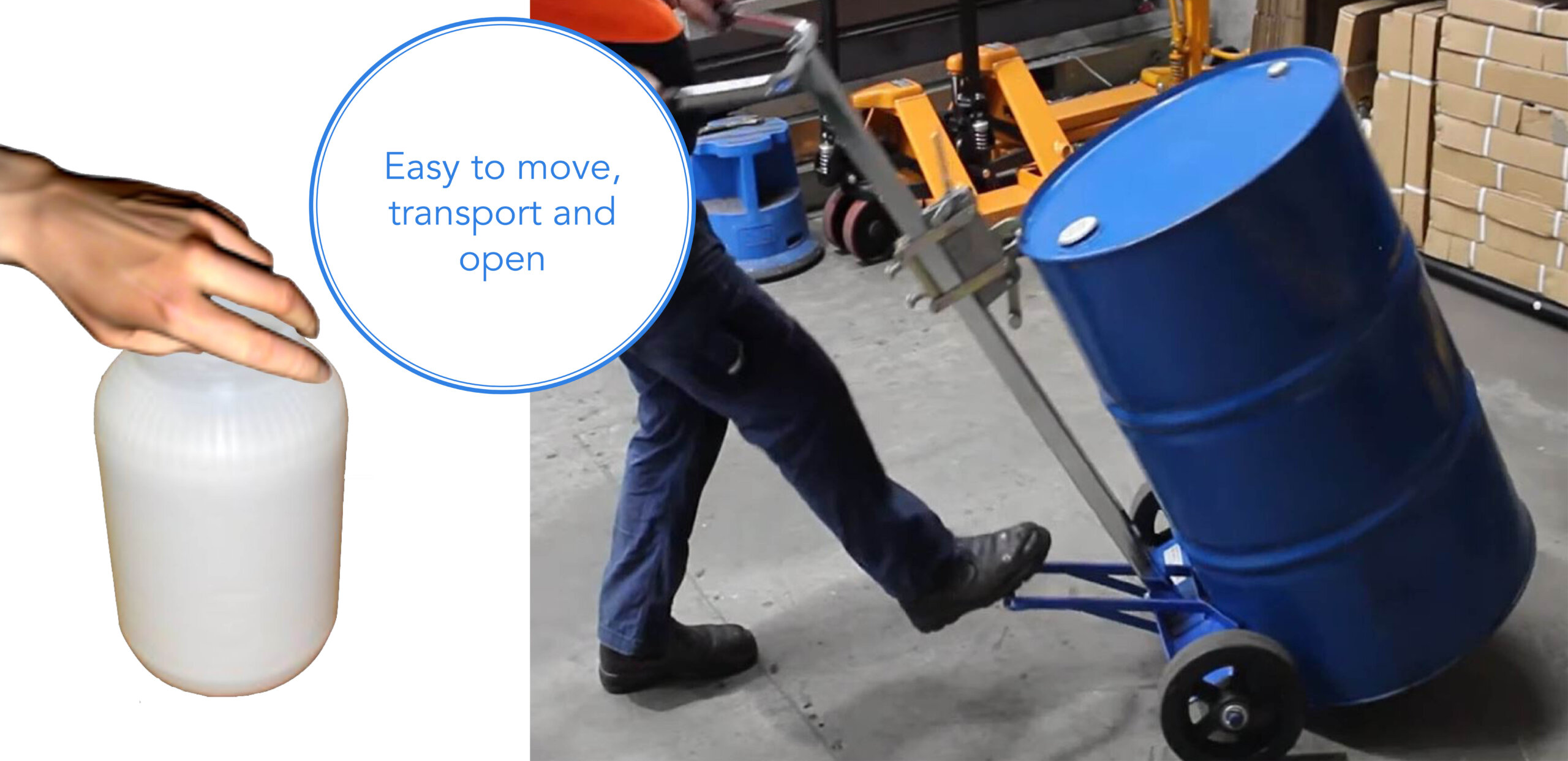

They say a picture paints a thousand words, you can see in the illustrations below the physical differences in the liquid & solid chemicals and how they will impact your workplace. The solid cannisters are conpact with easy to open lids, the amount of chemical in this small cannister will carry out the same amount of work as 2.7 liquid drums.

Other advantages of the compact design include;

Improved safety

- They are designed with gripped lids making them easy to handle and open

- The cannisters weigh only 5kg compared to a 250L drum, which means they can be lifted to their location with ease whereas the heavy liquid drums are awkward to move, especially in hard-to-reach places. This in turn poses little or no health risk and reduces potential back injuries.

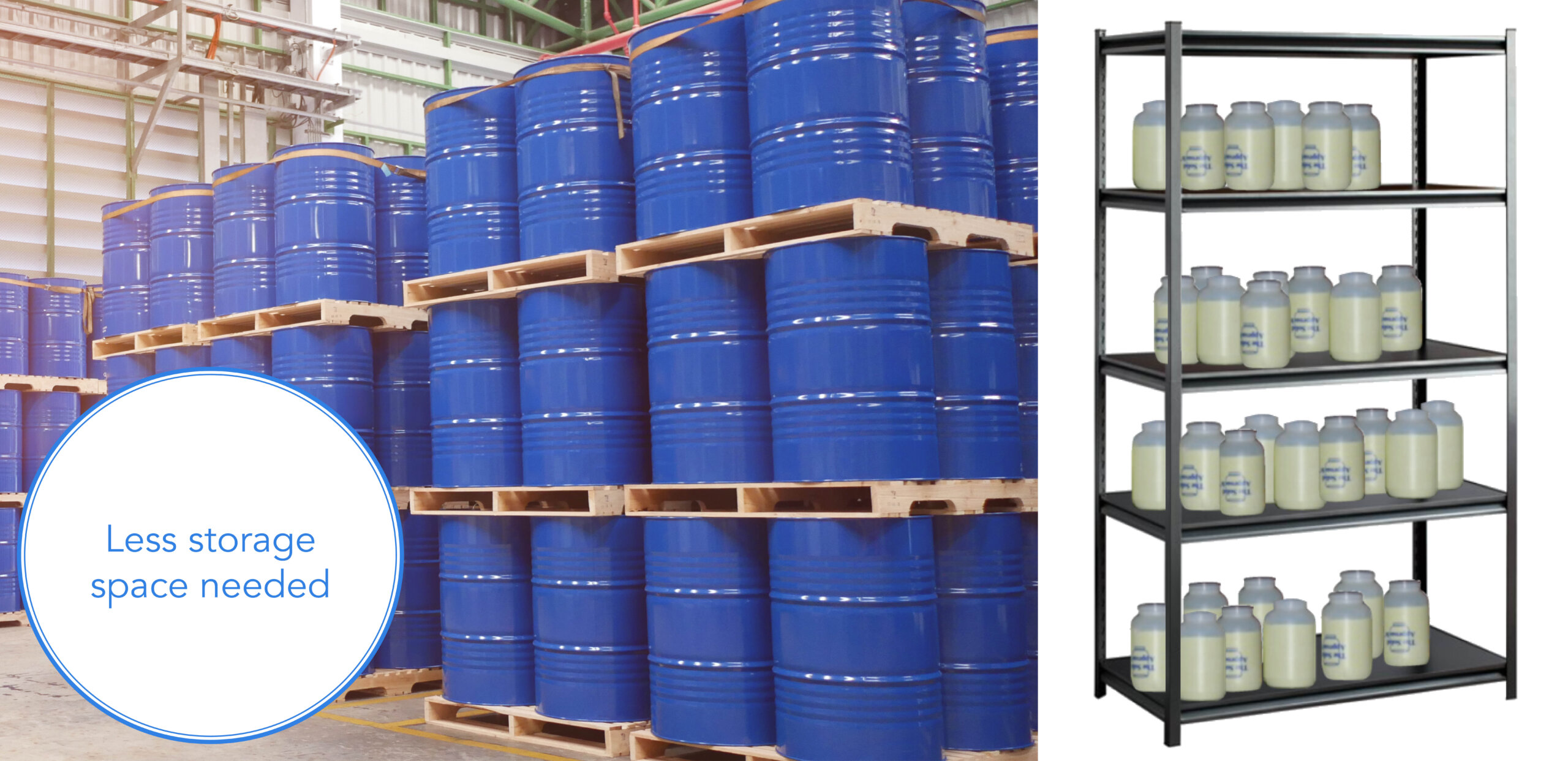

Maximises floor space

- Solid chemicals can be sored safely on shelves, make the floor space clear of any obstruction and optimising the floor space. With clever shelving design 60 cannisters can fit into the space of one 250L drum

Lowers Carbon footprint

- Less transportation is required due to their size, meaning less vehicles and emissions are emitted

- As one cannister carries out the equivalent of 2.7 drums, less frequent refills and deliveries are required. Not only is this lowering emissions, it is lowering transportation costs.

- The solid chemicals container and packaging can simply be placed into a recycling bin. Liquid-filled drums typically require handling considerations, triple rinsing upon disposal due to their hazardous nature, and other restraints that come with associated disposal costs. With solid chemicals there is no need to triple rinse as they self-rinse themselves.

- Solid chemicals use 0% of water in manufacturing most products compared to 50-90% water per volume in manufacturing liquid.

- Overall solid chemicals use 93% less emissions versus the equivalent liquid chemicals’ usage.

Solid Chemistry

Solid Chemistry

It cannot spill. Splashing and spilling of highly acidic or alkaline chemicals in the liquid drums can increase the risk of chemical exposure and inhalation incidents. This also creates hazardous areas and hazardous waste is spilled. A major advantage of the solid chemicals is that it cannot spill, thus no danger of health & safety issues such as slips or burns. This again will save waster on the clean up!

Increases Savings

Through the combination of these benefits you will see savings on freight costs when shipping lightweight chemistry bottles, Liquids can cost almost four-times the amount of solids to ship. In addition, solid chemicals do not require special containment or triple rinsing to comply with disposal requirements.

With liquid chemicals there are more risks that could impact your business – these will be reduced significantly when switching to solids.

Is it really worth changing over?

Yes. It may take a year or so to see the increased savings impact your business, but it will happen. From a business perspective transportation alone is big expense, especially since Brexit, switching to solids will decrease your transport requirements not only because of their size, but because you will require less refills also. Savings will also be seen in labour requirements, labour and disposal costs.

While changing over may not be seen as a necessity, more and more emphasis is being placed on sustainability and how businesses should be doing all they can to reduce their carbon footprint and changing to solid chemicals is one way to this.

Here at Aquachem we are proud to say that over 80% of our customers use solid chemicals and have noticed the impact it has had on their business. If you want to discuss further the benefits on changing, or the process of doing so please get in touch.