What to know about biofilms in Cooling Towers

If you have biofilm in your cooling tower, bad things are already occurring. For certain, your system is losing efficiency and you are losing money; but it is possible that there are bigger issues lurking just beneath that slime.

Biofilms in cooling systems increase corrosion, fouling, and deposition rates. This damages your equipment, increases energy consumption and costs you money. Biofilms in cooling systems can also harbour other dangers including Legionella and other harmful bacteria.

1.What Is Biofilm?

Sometimes also referred to as “bioslime,” biofilm is a matrix of polysaccharides and proteins that is enclosed by microorganisms that allows them to adhere to a surface and protect themselves from elements that may harm them.

Biofilms have an aerobic and anaerobic layer, which house their respective type of bacteria. It can form on system surfaces such as piping, sump walls, cooling tower fill, and heat exchangers.

Many biofilms have interesting properties that make them something that you should be concerned about, especially in a cooling tower. Here is a short list:

- Biofilm has incredible insulating properties, meaning that it greatly impedes heat transfer. In fact, in the case of a cooling tower, biofilm impedes heat transfer even more than scale deposition does!

- Biofilm is produced by microorganisms. They produce the biofilm so that they thrive within or underneath it, and some of these microorganisms can be quite nasty. Legionella in a cooling towerproduces a biofilm to protect itself; and legionella is the bacterium that is responsible for Legionnaires’ disease, a potentially deadly form of pneumonia.

- Due to their physiochemical properties, biofilms are extremely resistant to biocides. This means that simply increasing the amount of biocide in your water treatment is usually not enough to disinfect your cooling tower.

2. Why You Should Care About Biofilm?

Biological fouling is a challenge faced in many water applications in industrial plants. Biofilm formed due to the presence of bacteria in the water can reduce heat transfer efficiency.

Biofilm also can contribute to increased corrosion and maintenance requirements as well as lost productivity.

In cooling towers, biofilms cause microbial-induced corrosion (MIC) and equipment failures. In membrane systems, biofilms cause scaling and reduce the life of the equipment.

In summary, the 3 main reasons why you should care about biofilms in your cooling tower are:

- Loss of efficiency – As mentioned earlier, biofilm is an amazing insulator. If biofilm takes hold in your system you will lose efficiency. A biofilm layer that is less than one fifth of one millimeter thick can reduce efficiency by more than 10%!

- Potential serious damage – Some biofilms are caused by sulfite-reducing or iron-depositing bacteria. These types of bacteria can destroy steel. This can cause some costly repairs and downtime.

- Unnecessary and profound liability – Biofilms in your tower could indicate that you have a far more ominous issue like a water-borne pathogen. Legionella is one of the most ominous in this category. Legionella bacteria are responsible for causing Legionnaires’ Disease, a potentially deadly form of pneumonia. If you tower is located in an area that is close enough to send mist into a populated area, you have a potentially huge liability on your hands

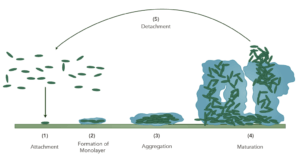

3. How Does Biofilm Form, And How Do I Prevent It?

Biofilm is formed when bacteria present in process water begin to stick to surfaces and indicate for other bacteria to join.

The rate of bacterial and biofilm formation increases in warmer condenser water and process cooling water. The factors listed below should be discussed when considering the control of biological growth and biofilm formation.

A) Eliminate or manage areas of low flow

Biofilm formation occurs more readily in areas of low flow – therefore it is important to eliminate all piping dead-legs, and ensure regular circulation of system water during periods of low load, the shoulder season, and the off-season.

B) Filtration

Both the availability of nutrients and the presence of collection surfaces for bacteria help contribute to bacterial growth and biofilm formation. Filtration is vital to remove the suspended solids associated with these factors. It is recommended that filters be monitored to ensure they do not become breeding grounds for additional bacteria because of the accumulation of these suspended solids.

C) Physical Cleanings and Disinfections

Physical cleanings on tower systems are recommended twice annually to help ensure proper biological control, especially following shoulder seasons or downtime. After the physical cleanings, which break up biofilm, it is important to disinfect the system to eliminate the newly freed bacteria.

D) Biocides

Biocides are employed to kill bacteria in many scenarios and consist of either an oxidizing or non-oxidizing agent. It is important to note that not all biocides penetrate biofilms equally, and many oxidizing biocides are very weak penetrators. Therefore, use of a biodispersant is recommended in conjunction with an oxidizing biocide.

4. How Do I Know If I Have A Biofilm Issue?

There are many devices available for monitoring biofilm formation, ranging from simple screen coupons to sophisticated devices which analyse electrical interferences. Unexplained reductions in heat exchange efficiency or visual indications such as slimes on sump walls or piping also indicate biofilm formation.

A simple test that is a general indicator of biological activity which may be used is a dipslide or an ATP level test. Although these will indicate bacteria levels present in the bulk water of the system, they don’t necessarily indicate the presence of biofilm.

Conclusion

The formation of Biofilm in your cooling tower can be very problematic and cause distress to your system. At Aquachem we have a number of treatment options available to help prevent and control formation – contact us today to find out more.