Cooling Towers; Their Purpose and Importance

Cooling Towers are structures that use water evaporation or airflow to remove excess heat from industrial equipment and HVAC systems.

They are essential for power plants, factories, processing / manufacturing plants, hotels and other large commercial buildings that depend on water circulation to discard heat from the building.

Cooling Towers vary of size, shape and type depending on the building’s needs and their cooling load. Larger plants will require large scale towers, where most other facilities have a cooling tower in their HVAC. No matter what the size, they must be properly maintained due to the dangers they can present.

How the cooling tower works

Every cooling tower performs the same fundamental process: hot water goes in and cool water comes out.

Wet cooling towers (also known as open-circuit cooling towers) are some of the most common, and they work like this:

- Hot water, which has been heated by industrial machinery or HVAC systems, is pumped to the cooling tower through pipes

- This hot water sprays through nozzles into a spill area, called “fill media,” this slows the flow of water through the cooling tower and exposes as much water surface area as possible for maximum air-water contact

- As the water flows through the cooling tower, it is exposed to air, from either an induced draft, forced draft, or natural draft

- When the water and air meet, a small amount of water is evaporated, creating the cooling action

- Where some of it evaporates, the cooled water that doesn’t evaporate pools in the bottom of the tower, where it gets recirculated back into your industrial equipment or air conditioning system

Common problems with cooling towers

Cooling towers require proper maintenance to ensure the most efficient operation. There are several cooling tower challenges:

- Corrosion

- Scaling

- Suspended Solids

- Microbiological Fouling Including Legionnaires’ Disease

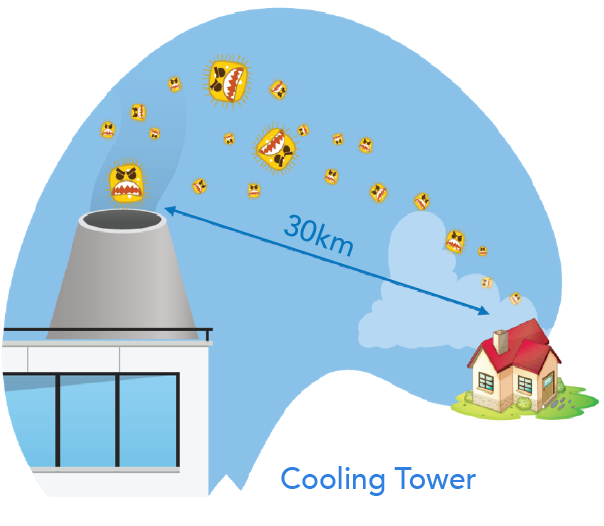

Due to their mode of operation, Cooling Towers create ideal conditions for microbial growth which can be dispersed over a wide area if not controlled properly. Operating between 20-45°C, Cooling Towers are the perfect place for legionella bacteria to grow.

Aerosols containing legionella can be dispersed with the evaporate or it can enter the air-conditioning system if there is a break between its ducts and those of the cooling tower or evaporative condenser. This can cause damage at a great distance, depending on the size of the installation, and so a large amount of people could contract the disease.

The routine maintenance of the cooling towers is very important to maximise their utilization and help avoid disasters which not only could cause health and safety issues but can interfere with your industrial processes or destroy your machinery.

In conclusion, cooling towers are an essential component of every building, and with the rapid increase of manufacturing the installation of cooling towers will only increase.

AquaChem has developed an extensive range of cooling water treatment chemicals to prevent the major problems associated with Cooling Towers. The AquaChem Legionella Water Hygiene Logbook System also enables operators of cooling towers and evaporative condensers to comply with the Irish Health Protection Surveillance Centre, UK and European Guidelines to minimise the risk of a Legionnaires’ disease outbreak.

For a quick understating of legionella in cooling tower systems please have a look through our online brochure here

Contact AquaChem for more information or advice on Cooling Towers.