Steam boilers are integral to many industrial processes, providing the necessary heat and steam for manufacturing, power generation, and other critical operations. However, maintaining these systems for optimal performance can be challenging, especially when dealing with hard water.

Hard water contains high concentrations of minerals like calcium and magnesium, which can lead to scale formation and inefficiencies in the boiler. This is where water softeners come into play, significantly improving the efficiency and lifespan of steam boilers.

What is Hard Water?

Hard water is water that contains high levels of dissolved minerals, primarily calcium and magnesium. These minerals are picked up by water as it percolates through mineral-rich soil and rock formations. The concentration of these minerals determines the hardness of the water, typically measured in grains per gallon (gpg) or parts per million (ppm).

How Water Softeners Work

Ion Exchange Process

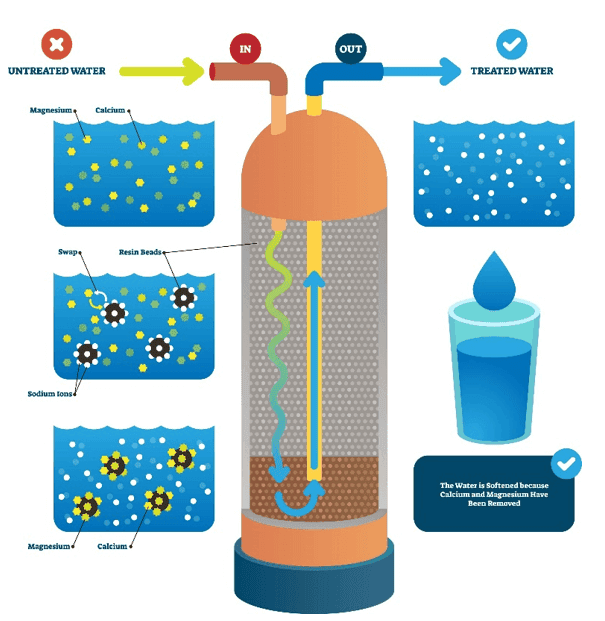

Water softeners mitigate the adverse effects of hard water through a process known as ion exchange. Here’s how it works:

Hard Water Entry: Hard water enters the water softener and passes through a resin bed composed of small, porous beads. These resin beads are charged with sodium or potassium ions.

Ion Exchange: As the hard water flows over the resin beads, the calcium and magnesium ions in the water are attracted to and bind with the resin. In exchange, sodium or potassium ions are released into the water.

Soft Water Exit: The resulting water, now free of calcium and magnesium ions, exits the water softener as soft water, ready to be used in the steam boiler.

Regeneration Cycle

Over time, the resin beads become saturated with calcium and magnesium ions and lose their effectiveness. The water softener then enters a regeneration cycle to recharge the resin bed:

Brine Solution: A brine solution, typically consisting of high-concentration sodium chloride (salt) or potassium chloride, is flushed through the resin bed.

Ion Replacement: The high concentration of sodium or potassium ions in the brine solution displaces the accumulated calcium and magnesium ions from the resin beads.

Rinse: The displaced calcium and magnesium ions are flushed away, and the resin bed is rinsed with water to remove any excess brine.

Recharged Resin: The resin bed is now recharged with sodium or potassium ions, ready to soften more hard water.

Benefits of Using Water Softeners in Steam Boilers

Enhanced Heat Transfer Efficiency: By preventing scale buildup, water softeners ensure that the heat exchange surfaces within the boiler remain clean and efficient. This allows for optimal heat transfer, reducing fuel consumption and improving overall boiler efficiency.

Lower Energy Costs: With improved heat transfer efficiency, the boiler requires less fuel to produce the same amount of steam. This leads to significant energy savings and lower operational costs.

Extended Boiler Lifespan: By preventing scale and corrosion, water softeners help extend the lifespan of the boiler, reducing the need for costly repairs and replacements.

Reduced Maintenance: Boilers with soft water require less frequent maintenance and cleaning to remove scale deposits, leading to lower maintenance costs and less downtime.

Improved Reliability: Consistent use of soft water reduces the risk of unexpected boiler failures and operational disruptions, enhancing the reliability of the steam system.

Environmental Benefits: Reducing fuel consumption not only lowers operational costs but also decreases greenhouse gas emissions, contributing to a smaller carbon footprint for industrial operations.

Conclusion

Incorporating water softeners into your steam boiler water treatment program is a smart investment that pays off in enhanced efficiency, lower energy costs, and prolonged equipment lifespan.

By preventing the detrimental effects of hard water, water softeners ensure that your steam boiler operates at peak performance, providing reliable and efficient steam production for your industrial processes. Embracing water softening technology not only improves operational efficiency but also contributes to a more sustainable and environmentally friendly industrial practice.