Energy Savings in Water Treatment – Water Usage Reduction

Water is a precious resource that is essential for our survival and plays a crucial role in industrial processes. However, excessive water consumption in industrial settings not only strains our water supplies but also results in significant financial and energy costs.

By implementing water usage reduction strategies, businesses can realize substantial savings while promoting sustainability.

In this blog, we will explore the various reasons why water usage reduction in industrial settings is a cost-effective choice that saves money and energy.

Reduced water supply costs

Industrial facilities require significant amounts of water for various operations, from manufacturing processes to cooling systems. However, this high demand comes at a price. By reducing water consumption, businesses can directly reduce their water supply costs. This includes expenses associated with sourcing, treating, and disposing of water. Companies can avoid paying hefty fees for procuring water from external sources, as well as reduce expenses related to water treatment and wastewater disposal. These cost savings directly impact the bottom line and improve financial performance.

Lower wastewater treatment expenses

Water usage reduction not only decreases the amount of water consumed but also results in reduced wastewater generation. Consequently, industrial facilities can expect lower expenses for wastewater treatment.

Treating and disposing of wastewater can be a costly process, involving the use of chemicals, energy-intensive treatment technologies, and compliance with stringent regulatory requirements. By minimizing wastewater production, businesses can minimize the associated expenses, including the cost of treatment chemicals, energy consumption during treatment processes, and penalties for non-compliance. Moreover, reducing wastewater generation also lessens the burden on local water treatment facilities, benefitting the community as a whole.

Energy savings in water pumping and heating

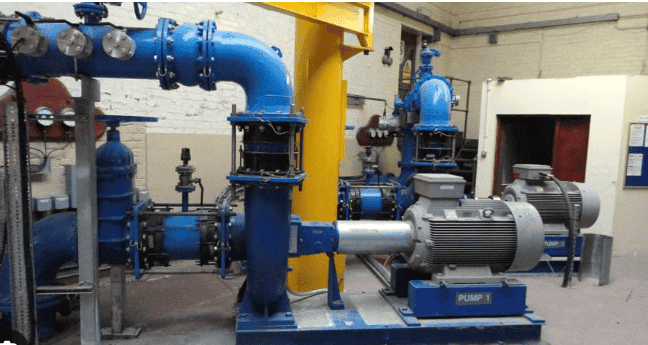

Water pumping and heating operations are energy-intensive in industrial settings. By reducing water usage, companies can achieve significant energy savings. Pumping water from sources such as wells or municipal systems requires substantial energy inputs. Similarly, heating water for various industrial processes can be a major energy drain. However, by implementing water conservation measures, businesses can decrease the energy required for water pumping and heating.

This translates into reduced utility bills and improved energy efficiency. Investing in efficient water pumps and heat recovery systems can further amplify these energy savings, providing long-term financial benefits.

Enhanced equipment efficiency

Water is often utilized for cooling purposes in industrial machinery and equipment. However, excessive water usage can result in inefficiencies and increased maintenance costs. By optimizing water consumption and implementing efficient cooling systems, businesses can improve equipment efficiency. This leads to energy savings and extends the lifespan of machinery, reducing maintenance and replacement expenses. Furthermore, efficient cooling systems reduce the risk of equipment failure and downtime, ensuring consistent productivity. By reducing water-related disruptions and maximizing operational uptime, companies can enhance their overall profitability.

Improved productivity and reduced downtime

Water scarcity or interruptions in water supply can severely impact industrial operations, resulting in downtime and decreased productivity. By prioritizing water usage reduction and ensuring a reliable water supply, businesses can mitigate these risks and avoid costly interruptions. Consistent production levels lead to increased profitability and customer satisfaction. Implementing water conservation measures, such as leak detection and efficient water management practices, can help identify and address water-related issues promptly. Additionally, promoting a culture of water conservation among employees can further contribute to sustained productivity and operational efficiency.

Conclusion

Water usage reduction in industrial settings is not only an environmentally responsible choice but also a financially astute decision. By implementing strategies to minimize water consumption, businesses can achieve substantial cost savings, including reduced water supply and wastewater treatment expenses. Furthermore, energy savings in water pumping, heating, and equipment cooling further contribute to