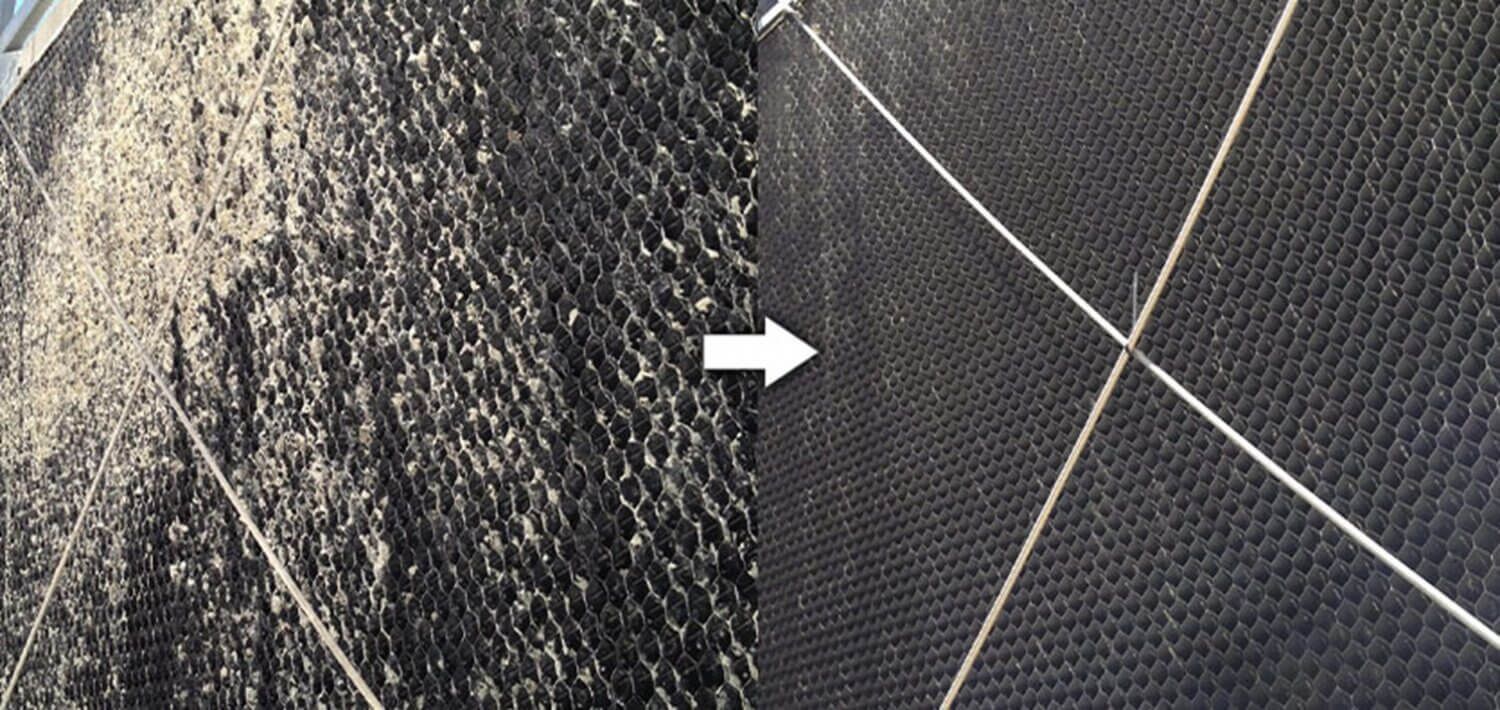

Removal of fouling and scaling from a cooling tower

Industrial water treatment is a critical component that often consumes a substantial amount of energy. Cooling towers, in particular, play a pivotal role in dissipating heat generated during various production activities. However, cooling towers require filtration to effectively remove scale, dirt, and other impurities in the water. The implementation of proper filtration will not only improve efficiency, but it will also save energy and significantly reduce maintenance costs.

ENERGY SAVINGS

Reduced Fouling and Scaling

Cooling towers face a constant battle against fouling and scaling. However, filtration assists in removing suspended solids and particulate matter, which have a negative effect on heat exchange surfaces and heat transfer efficiency. By preventing fouling and scaling, filtration ensures that heat exchangers operate at peak efficiency, reducing the need for additional energy consumption.

Improved Heat Transfer:

Clean water promotes better heat transfer in cooling towers. Therefore, when heat exchangers are free from deposits and impurities, they can transfer heat more efficiently. As a result, cooling towers can achieve the desired temperature reduction with less energy input.

Lower Pumping Costs:

Not only does filtration contribute to cleaner water but it also reduces the resistance to water flow, alleviating the workload on pumps. This extends the life of pumping equipment, lowering pumping costs and, consequently, reduced energy consumption.

Extended Equipment Life:

Cooling tower filtration promotes the longevity and reliability of the entire system. This results in fewer replacements and less frequent maintenance, aiding to the energy savings associated with the manufacturing, transportation, and installation of new equipment.

Lower Chemical Treatment Costs:

Proper filtration reduces the need for excessive chemical treatments as clean water requires fewer chemicals to control corrosion, scale, and biological growth. This minimises the environmental impact associated with the production and disposal of water treatment chemicals.

COST SAVINGS: REAL-LIFE STORY

Let’s consider a case study to illustrate the tangible cost benefits of having an effective filtration system in your cooling tower.

Image: Industrial Cooling Tower

Details:

Year: 2022

Production: 140 m3/h

Degree of Filtration: 135 micron

Water Source: Mains water

Solution: Side Stream Filtration

A manufacturer in the thermoplastics sector was having an issue with substantial build-up of suspended solids, such as plastic shavings, pellets, environmental debris, and makeup water residues, in their cooling tower. This accumulation was leading to increased production shutdowns, which were critical for maintaining the required precision in the process water temperature.

To combat this issue, a side stream filtration system was implemented into the cooling tower. This piece of filtration technology was chosen for its ability to ensure minimum water and energy consumption while effectively filtering complex particles from the industrial process.

The manufacturing company noticed significant energy and cost savings in just 1 year of installing the side stream filtration system to their cooling tower.

Results after Year 1:

65% decrease in maintenance and inspection shutdowns

40% increase in the lifespan of numerous cooling tower components

30% savings on cost of chemicals due to a reduction in chemical consumption

Payback of the filtration system will be complete within 18 months

Conclusion:

In the world of water treatment, the impact of cooling tower filtration on energy savings cannot be overstated. It’s not just about maintaining clear water; it’s a strategic move towards sustainability, cost-effectiveness, and enhanced operational efficiency.

By embracing cooling tower filtration, businesses not only protect their bottom line but also contribute to a more sustainable and efficient future. It’s time to recognize the true value of filtration as a cost-effective solution that goes beyond water clarity, driving long-term savings and operational excellence in the realm of water treatment.