Risycor Corrosion Monitoring

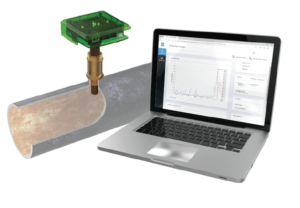

Risycor Corrosion Monitoring – Smart sensor technology that warns you when corrosion threatens your heating or cooling system.

In closed systems, corrosion can still occur despite limited exposure to external elements. In such cases, the primary cause of corrosion is often the presence of dissolved gases and impurities within the closed system, which can create localized corrosive environments.

As these impurities concentrate at specific locations, they facilitate corrosion initiation and propagation, leading to material degradation over time.

That’s why regular monitoring and preventive measures are crucial to mitigating corrosion in these environments and ensuring the longevity and reliability of the system.

Why use the Risycor Corrosion Monitoring

Real-Time Monitoring:

Corrosion monitoring techniques continuously provide real-time data, allowing you to track corrosion rates and material degradation over time. In contrast, coupons only offer a snapshot of corrosion at specific intervals when they are retrieved and analyzed.

Real-time monitoring enables quicker identification of potential corrosion issues, facilitating timely intervention and preventive measures.

Time Efficiency:

The most significant advantage of HASL corrosion monitoring is its ability to provide rapid results. Instead of waiting for weeks or months for coupon data, you can obtain equivalent information within days or weeks using corrosion monitoring, significantly speeding up the evaluation process.

This enables engineers to test and evaluate multiple materials or coatings in a relatively short period, expediting the development of corrosion-resistant solutions.

Cost Savings:

Traditional long-term exposure testing can be costly and time-consuming.

HASL significantly reduces these expenses by compressing testing periods, ultimately resulting in considerable cost savings for industries. The ability to test multiple materials and coatings efficiently and identify potential corrosion issues early on can lead to significant cost savings in maintenance, repair, and asset replacement.

Data Accuracy:

HASL corrosion monitoring delivers precise and reliable data,

Offering valuable insights into material behavior under accelerated corrosion conditions. This data can be instrumental in improving the design and selection of corrosion-resistant materials for critical applications.

This comprehensive information enables a deeper understanding of the corrosion mechanisms, allowing for better-informed decisions regarding material selection and corrosion protection strategies.

Risk Reduction:

By obtaining data on material behavior in accelerated corrosion conditions, potential weaknesses can be identified early in the development process,

Thus reducing the risk of costly failures in real-world applications.

Non-Intrusive Monitoring:

Corrosion monitoring techniques are often non-intrusive, meaning they do not require the removal of samples like coupons do.

This non-intrusive nature eliminates the risk of altering the local environment during sample extraction and provides a more accurate representation of in-situ corrosion behavior.

“….the benefits of these monitors which include energy management as well as from an operations perspective in striving for longevity in our installations which is exciting.

I particularly like the ability to view this information via the cloud and therefore a 4G solution is required which can be provided by an industrial router being provided which avoids the hurdles and risks of trying to install on our Trusts IT networks ad requiring a gateway for third-party contractors.”

Assistant Director of Estates at NHS Trust

Understanding HASL Corrosion Monitoring:

HASL corrosion monitoring is an accelerated testing method that simulates corrosion in a shorter timeframe compared to natural environmental exposure.

By employing elevated stress factors, such as temperature, humidity, and other corrosive agents, HASL can replicate years of corrosion behavior in a matter of weeks or months.

This technique enables researchers to assess the long-term effects of corrosion rapidly, making it a valuable tool for evaluating materials, coatings, and protective measures.

Conclusion:

Corrosion monitoring techniques, such as HASL, provide numerous advantages over traditional coupon-based methods. They offer real-time and continuous data collection, more comprehensive analysis, faster results, and the ability to simulate specific environmental conditions.

As industries seek more accurate and efficient ways to combat corrosion, corrosion monitoring continues to gain prominence as a valuable tool for optimizing material selection and corrosion protection strategies.