Keeping your cooling towers operating properly requires regular cleaning and maintenance to prevent microorganism growth and debris build up.

During process cooling, cooling water absorbs large volumes of airborne particulate while the cooling tower acts as an air scrubber, filtering the surrounding air. With time, these fine particles build up and settle within the system, affecting cooling performance while lowering the life of wetted subcomponents.

The presence of these in high volumes can be harmful to a cooling tower, affecting the performance of the entire system. Fine particulates under 5 microns in size present the following challenges

Component clogging

This causes irregular distribution of the water across the cooling tower.

Heat transfer inefficiencies

This requires increased energy and water, driving costs upward.

Scaling, fouling and bacterial growth such as Legionella.

These cause quick degradation of components, resulting in early replacement, increased maintenance costs and health concerns.

Unscheduled shutdowns and cleaning.

These lead to increased operating costs.

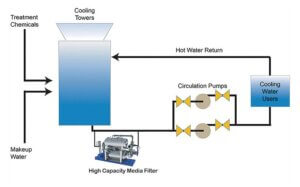

A high efficiency media filtration system can optimize water treatment efforts. Side stream filtration is often used to filter a portion of the system’s circulating, this can remove debris and particles; adversely affecting the cooling loop and its components, including the heat exchangers, chillers and tower.

Signs your cooling tower would benefit from filtration

Observing the following conditions in your cooling water system are signs that your facility would benefit from using a side-stream filtration system:

- The makeup water source is high in suspended solids, iron, biological and organic activity.

- There is a concern for biological growth even though a strong biocide treatment is in effect.

- More frequent cleaning of the heat exchangers and chillers is necessary. (Regular cleaning should occur approximately every 12 to 16 months.)

- There are signs of excessive rates of corrosion within the water loop and its components.

- There is a loss of heat transfer and efficiency in the overall cooling system.

- A high buildup of solids occurs within the sump or fill of the cooling tower.

Side-stream filtration technology generally falls into general categories:

- screen filters

- centrifugal filters

- bag and cartridge filters

- sand/media filters

- high efficiency media filters

- purities

Filter technology is evaluated based on its performance in filtering fine particulate (ranging from 1 to 50 microns). Choosing the appropriate side-stream filtration system can yield significant savings for processors. You water treatment experts can advise on what is best for you. Over time, users of side-stream filtration systems will experience reduced maintenance costs and chemical consumption.

Cleaning your cooling tower

Dirty and fouled cooling tower water often plagues maintenance teams that manage industrial cooling towers and so cooling towers should be regularly cleaned in order to ensure that they function at peak efficiency and to keep employees and visitors safe.

As mentioned, dangerous bacteria can build up in an unmaintained cooling tower, causing illness and even death. Additionally, a cooling tower marred with sludge or corrosion will not transfer heat efficiently, leading to a higher cost of operation for less performance.

Most cooling towers should be cleaned twice per year but especially before the warmer months to ensure that the system comes out of its off-season in good repair. With increased debris and organic matter, manually cleaning a cooling tower can take days to accomplish and so the less debris in the cooling tower the easier it is to clean.

Conclusion

As with all process cooling applications, it is important to understand that your water and the suspended solids it contains are adversely influencing the overall system.

For such applications, side-stream filtration can yield a high return on investment for facility and building / maintenance managers.

A cleaner system requires fewer resources to maintain its integrity, keeping the overall system performing as intended. Potentially, this offers decreased downtime and increased uptime.

Get in touch with us today to find out how clean your cooling water is and how we can help you.