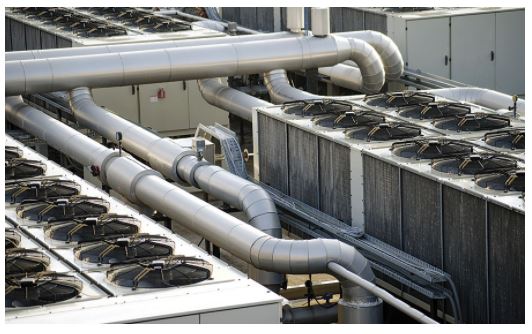

Without a water treatment plan, it is impossible tell when significant issues such as scaling, corrosion or contamination might occur. If this fouling occurs in your cooling tower it can result in a complete loss of productivity, extended downtime, and expense for repairs.

Cooling towers need water treatment in order to keep operational costs low and cooling efficiencies high. If you don’t treat your water – or choose the wrong chemicals – your systems are at a higher risk of fouling and contamination.

Nearly all cooling towers (and HVAC systems) benefit from using chemicals in their water. These chemicals, which vary in both function and type and will help ensure that you:

- Maintain high water efficiency

- Increase cooling tower performance

- Reduce corrosion and scale

- Improve system longevity

Cooling tower water treatment also often uses a variety of mechanical filtration and side-stream filtration methods, but the performance and effect of your water treatment are often dependent on what chemicals you use.

.

.

.

.

What are the chemicals used?

Chemically treating cooling tower water helps balance the chemical properties of the water, putting it in the right state for other methods of treatment. The main chemicals used for colling tower water treatment are:

Corrosion and Scale Inhibitors

To prevent the degradation of your cooling tower, corrosion and scale inhibitors help delay or prevent formation in your system. The inhibitors are highly effective in preventing the formation, and only require a low dosage.

Corrosion Inhibitors

Corrosion is one of the main issues cooling towers face, this is caused by the minerals in the water. Over time corrosion will cause degradation of metal parts in the tower, causing system malfunctions, while also weakening the structure of the cooling tower.

To prevent and minimize the rate of corrosion, corrosion inhibitors are used. The inhibitors create a thin layer or coating on the surface of the metal which prevents the access of metal surface.

Scale Inhibitors

Scaling and deposition is also another major problem in cooling towers. When an unwanted material or contaminant in the water builds up in a certain area, it can create deposits that grow over time. This can cause issues ranging from the narrowing of pipes to total blockages and equipment failures.

Evaporation takes place in cooling towers and because of this, the scale-forming minerals present start to concentrate and because of that scaling occurs.

Algaecides and Biocides

Controlling microbiological growth is key to maintaining optimal water conditions. In a cooling tower, several types of impurities are present in the water such as organic, inorganic, and other salts. Over a period of time, micro-organism growth occurs along with algae formation.

Because these materials are alive, they can proliferate and overtake a cooling tower in a surprisingly short time. For this reason, most cooling towers are treated with some sort of biocide (anti-biotic) to prevent a sudden bloom or burst of organic life that fouls components in the system and can cause health concerns.

Using carefully selected biocides in conjunction with dispersants, you can control any buildup and the resulting bio-corrosion that occurs under slime deposits.

Sanosil C is our preferred choice of biocide for cooling towers, its unique combination of hydrogen peroxide and silver has a long lasting effect and destroys any biofilms present in the water.

pH Adjusters

Alkalinity adjusters or pH adjusters help reduce corrosion in a cooling tower, as lower pH levels can accelerate corrosion.

Cooling tower water pH is maintained at 7.0 as neutral as highly acidic or basic water can damage cooling tower parts and also equipment in which that water is circulated in the system. As pH increase or decreases, it can cause corrosion to the cooling tower parts, hence pH is maintained at 7.0.

Ensure you have the right water treatment plan

Implementing a regular water treatment program for your cooling tower is necessary to maintain safe and reliable operations.

To maintain the quality parameters of cooling tower water, different types of chemicals are required, these used to treat cooling water so that it remains as productive as possible for the equipment and pipes.

We offer a full range of high performing cooling tower chemicals to help increase the longevity, efficiency, and effectiveness of your cooling tower.

As experienced water treatment specialist we can analyze your water situation and advise you on which chemicals would be needed most. Contact us to find out more.